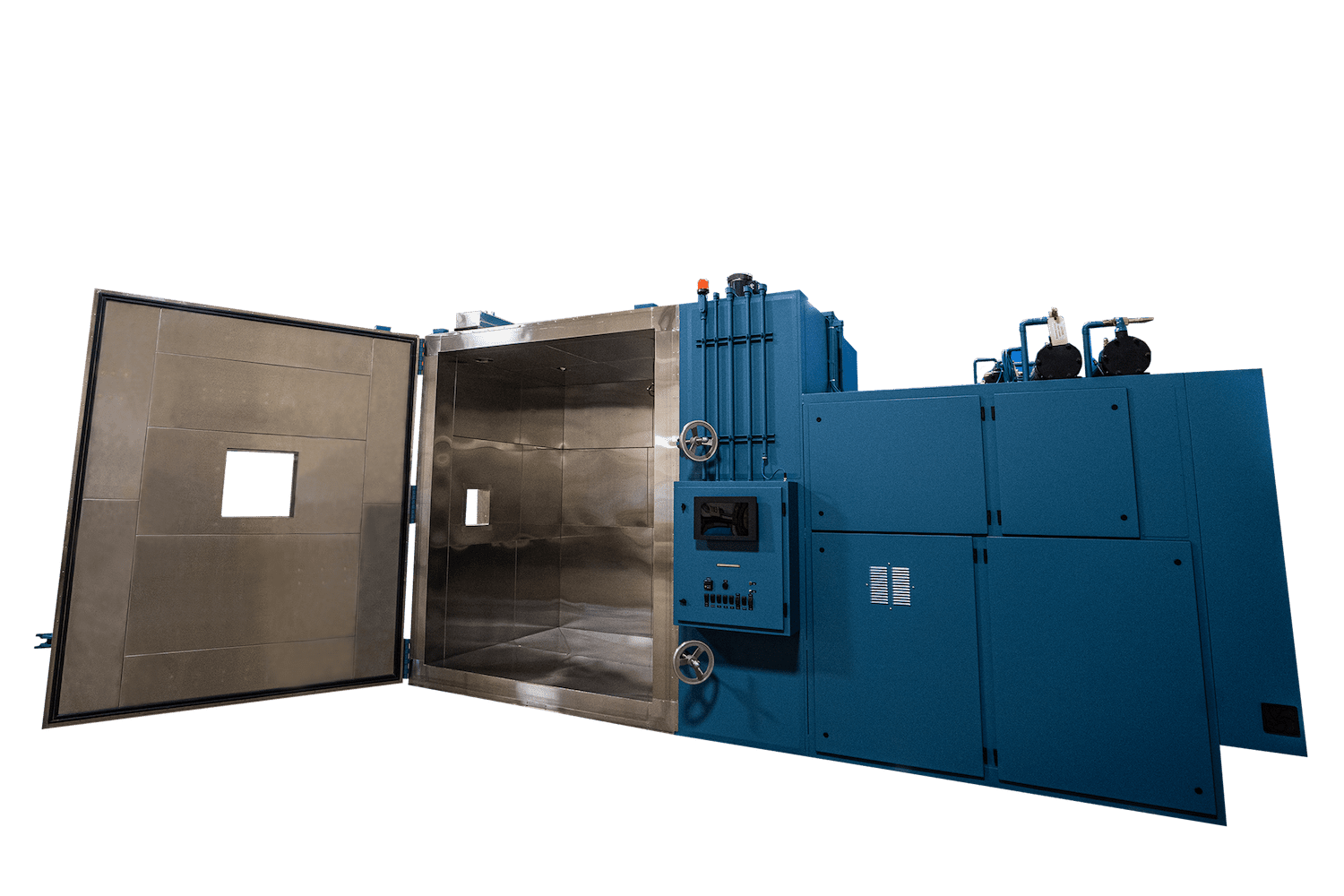

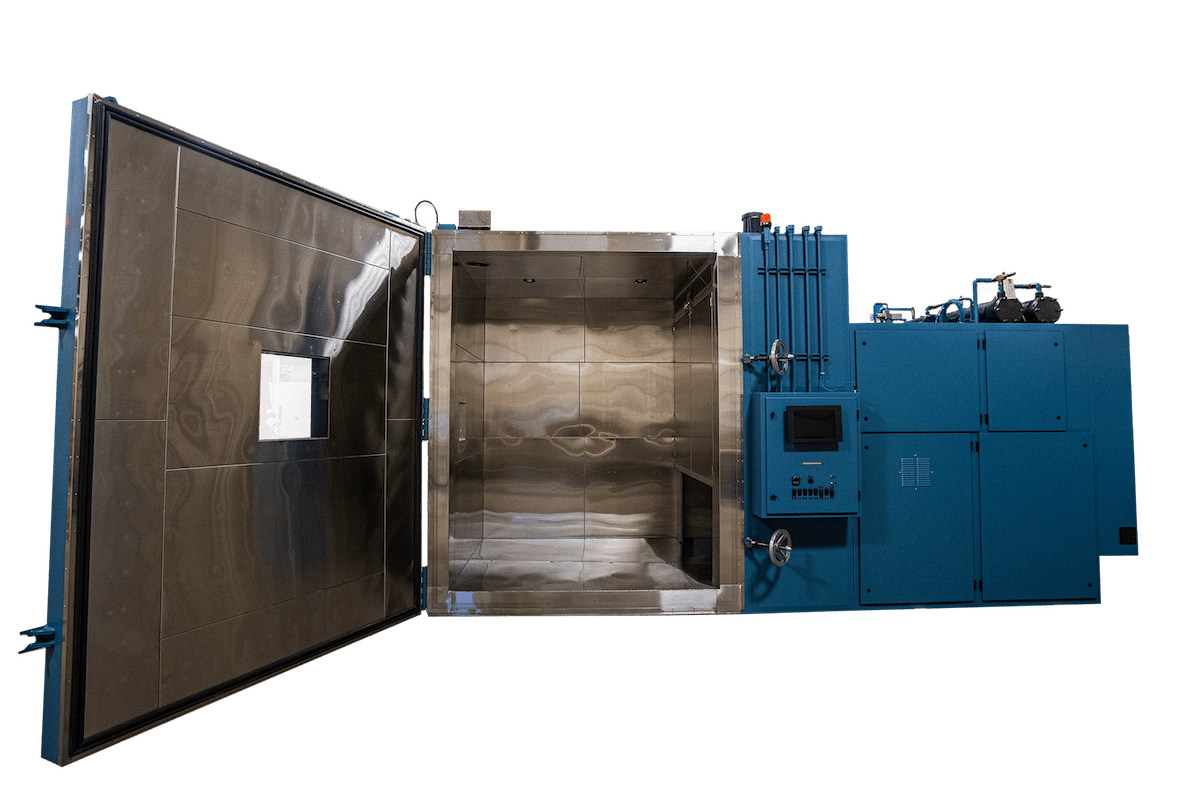

Walk-In/Drive-In Solid Construction Temperature/Humidity Chambers

Russells Technical Products W-Series welded construction walk-in/drive-in chambers are ideal for high temperature and high humidity simulation. Their solid, one piece construction allows for rapid thermal change rates, ultra low temperature cooling, and prolonged soaks at extreme temperatures. With a wide variety of plenum options and configurations, our W-Series test chambers can be designed to meet your exact specifications.

About Solid Construction Walk-in Temperature/Humidity Chambers

Moisture buildup can be destructive to products, especially electronics, causing corrosion and oxidation. Russells’ solid construction W-Series temperature and humidity test chambers afford maximum durability and performance for your most demanding simulation test requirements.

Controlled Testing Environment Capabilities

- Steady-state or cyclical temperature and temperature/humidity tests

- Rapid-rate temperature/humidity cycling tests (>9°F/5°C/min.)

- Elevated temperature heat aging (>356°F/180°C)

- Ultra low temperature cryogenic tests to -180°C/-292°F

- Temperature range for single stage refrigeration:

- -32°C/-25°F to 180°C/356°F

- Temperature range for cascade refrigeration:

- -73°C/-100°F to 180°C/356°F

- Humidity Range:

- 10% to 95% RH within the bounds of a 185°F/85°C max. dry bulb and a 40°F/4°C min. dewpoint

- Brushed 304 series stainless steel liner, hermetically welded and dye checked

- Welded steel frame

- Durable blue enamel finishes (custom colors available)

- Capable of handling extreme temperature and humidity

- Full opening chamber door with dual gaskets (many door configurations available)

- Fiberglass insulation, .25k factor

- Removable access panels to serviceable components

- Can be equipped with battery testing safety features according to EUCAR hazard safety level

- Through‐wall access ports with foam plugs

- Viewing windows

- Refrigeration gauges

- Refrigeration sound deadening package

- Remote refrigeration systems

- LN2 boost cooling

- Humidity water demineralizer

- Dry air purge system

- Desiccant dehumidifier

- Personnel entrance airlock

- Entry ramp

- Running time meter

- Electrical disconnect switch

- Product safeguard redundant over/under temperature limit

- Circular or electronic chart recorders

- Computer communications, networking, data‐logging software

- Free standing remote instrument console

- Additional safeguards for battery testing

- Low or zero ozone depletion refrigerants

- Energy-saving refrigeration bypass capacity control

- Low stage desuperheater

- Oil pressure switches

- Compressor suction and discharge pressure switches

- Air or Water cooled condenser

- Vapor tank and condenser ASME certified

- Compressor overload protection

- High-stage compressor crankcase heater

- Compressor head fans

- Low-stage oil separator

- All piping joints silfos or silver soldered

- Stainless steel compressor condensate pans

- All wiring meets NEC/NFPA standards

- 120v control circuit transformer

- Fully enclosed electrical panel

- All circuits fused or circuit breaker protected

- Full system function switches with system status pilot lights

- Incandescent interior lighting

- All wiring numbered or color coded

- High Temperature limit safety

- Master heating circuit contactor

- Air circulator/heater interlock

- Balanced load on 3 phase power

- 3rd party NRTL/CSA/CE marking available