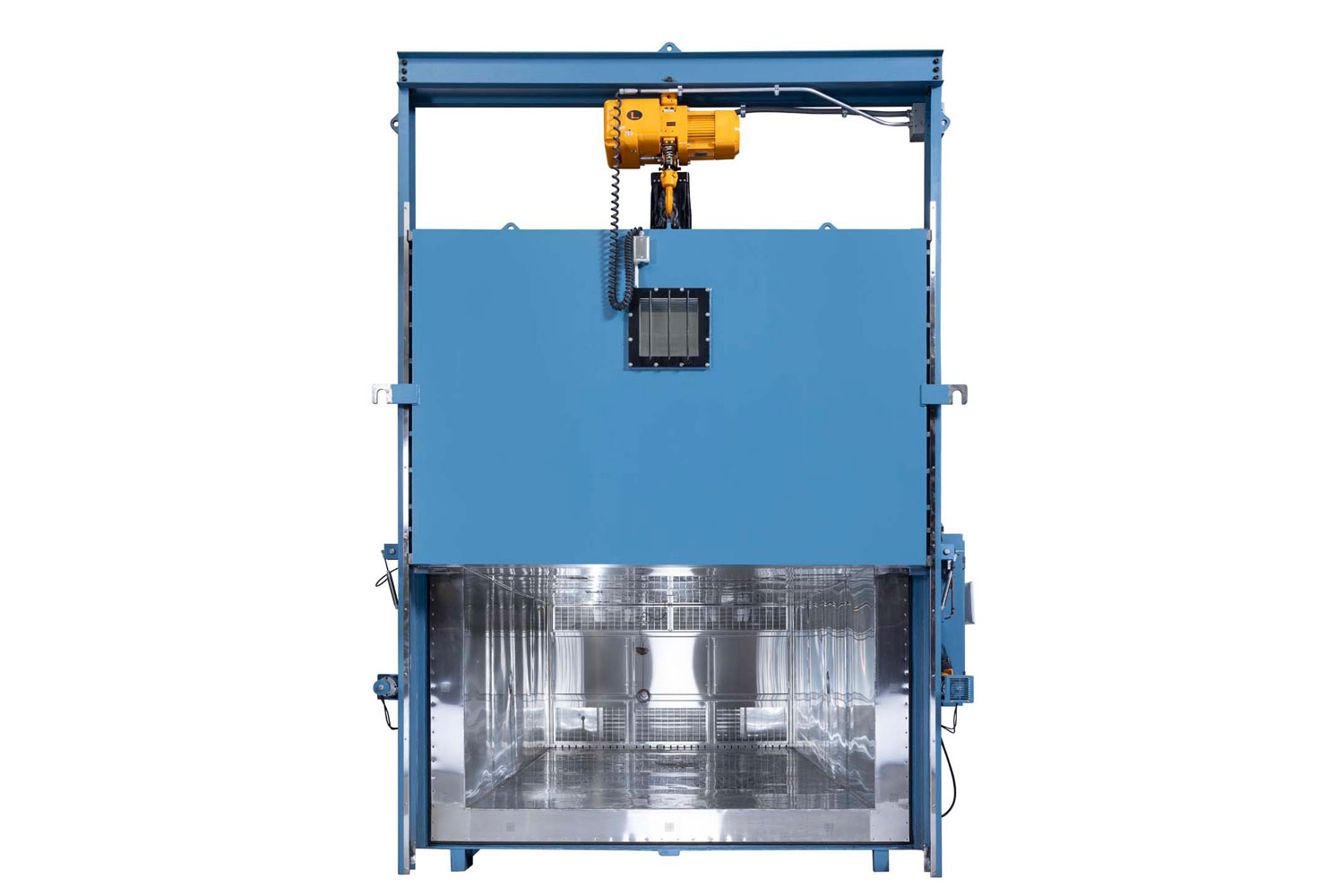

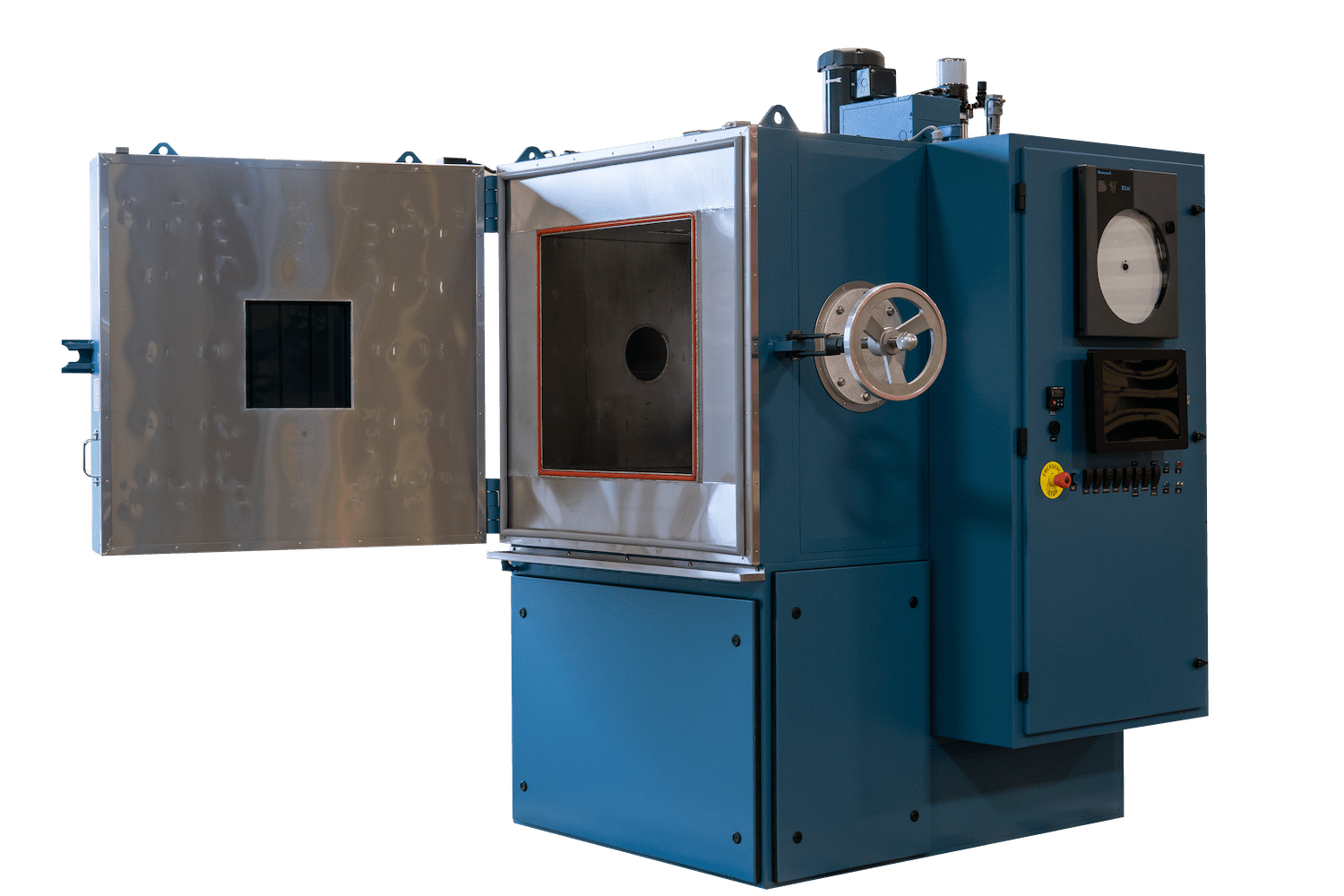

Altitude Test Chambers

Altitude testing is essential for military, industrial, aviation, and consumer applications where products or components experience low-pressure environments or must withstand rapid decompression combined with climate control. Russells RH (reach-in) and WH (walk-in) Series altitude chambers offer the performance, flexibility, and reliability required for today’s mixed environmental testing standards. An RTP altitude test chamber controls the temperature environment for product testing while simulating various altitudes, or can be used for stand-alone temperature and humidity testing. Russells can manufacture your altitude test chamber to meet MIL-STD, RTCA DO-160, and other test specifications.

What is an Altitude Test Chamber?

Our altitude test chambers control the temperature and/or humidity environment for testing your product while simulating various altitude conditions from site level to 200,000 feet. Some test standards require combined testing, therefore we offer a wide range of conditions including temperature, altitude, humidity, and vibration. Our altitude test chambers can meet RTCA DO-160 and MIL-STD-810H test specifications for icing and rapid decompression for avionics cabin pressure testing. Our rapid decompression option simulates sudden altitude change from 8,000 ft. to 60,000 ft. in 15 seconds.

Controlled Testing Environment Capabilities

- Altitude

- Temperature

- Temperature and altitude (temperature controllable to 65,000 ft./20,000m)

- Temperature and humidity at site level

- Temperature, altitude, and vibration

- RTCA DO-160 icing and various other combined environmental tests

- Rapid Decompression

Altitude Test Chamber Features

- Brushed 304 series stainless steel liner, hermetically welded and dye checked

- Welded external or internal pressure member construction

- Welded steel frame with removable access panels to service components

- Full opening chamber door with heavy duty latch

- Heavy duty journal bearing door hinges

- Durable blue enamel finish *custom colors available

- Vacuum systems for MIL-STD-810 and RTCA DO-160 rapid decompression testing

- Through-wall access ports with bolted vacuum tight covers

- Viewing windows

- Adjustable shelves

- Refrigeration sound deadening package

- Remote refrigeration systems

- LN2 boost cooling

- Air cooled condenser

- Humidity water demineralizer

- Dry air purge system

- Running timer meter

- Electrical disconnect switch

- Minimal spark electrical system

- Additional safeguards for battery testing

- Low or zero ozone depletion refrigerants

- Low stage desuperheater

- Oil pressure switches/transducers

- Compressor suction and discharge pressure switches/transducers

- Air or water cooled condensor

- ASME certified pressure vessels

- Compressor overload protection

- High stage compressor crankcase heater

- Compressor head fans

- Low stage oil separator

- All piping joints silfos or silver soldered

- Stainless steel compressor condensate pans

- All wiring meets NEC/NFPA standards

- UL-508b certified control panels

- 120 volt control circuit transformer

- Fully enclosed electrical panel

- All circuits fused or circuit breaker protected

- Full system function switches with system status pilot lights

- Interior lighting

- High temperature limit safety

- Redundant heating circuit safety contactor

- Air circulator/heater/high altitude interlock

- Balanced load on three phase power

- Third party NRTL/CSA marking available

- russellsOne touch screen altitude, temperature, and humidity programmer controller

- Automatic altitude climb and dive control valves

- Computer communications, networking, and data logging

- High speed data acquisition for rapid decompression applications

- Absolute pressure altitude sensor/transducer

- Solid state humidity sensor

- Product safeguard FM approved over/under temperature limit

- *Commerical off-the-shelf controllers available upon request