Reach-In Test Chambers

Reach-In Test Chambers

The Elite G-Series reach-in environmental test chambers line includes industry-leading features and accessories which offer superior performance and reliability.

Offered in five standard sizes, our temperature/humidity chambers provide users the widest range of temperature or temperature and humidity environments on the market.

Temperature and humidity chambers are an excellent choice for thermal cycling, steady state conditioning, product reliability testing, and other applications.

Handle: ergonomically designed for single-handed access to the chamber.

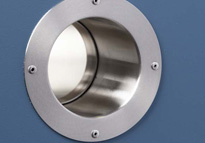

Window: multi-pane and heated to ensure dryness and fog inhibition at low temperatures.

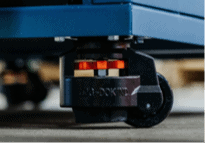

Casters: 4” heavy duty casters for leveling and mobility.

Door: 180° degree opening, with two silicone gaskets and corrosion resistant hinges.

Exterior: Powder coated 16 gauge welded steel with gasketed removeable panels covering insulated areas.

Controller: Watlow microprocessor controller with RS-232 data interface

Access Port: 3” stainless steel with adaptable location.

Shelves: Heavy duty, polished stainless steel, rated to 75lbs.

- Overview

- Features

- Optional Add-Ons

- Refrigeration

- Humidity

- Controls

- Electrical

- Specifications Get Quote

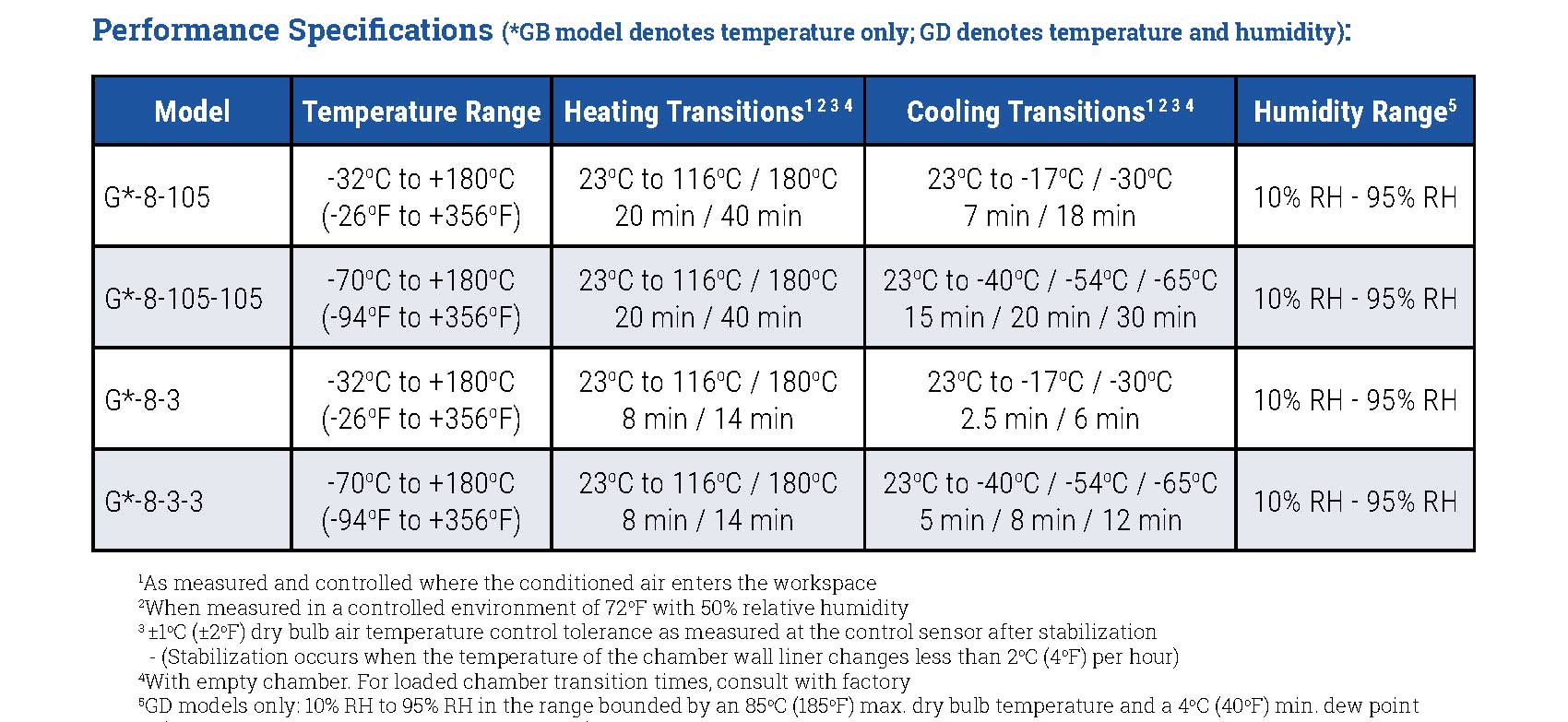

The G-8 Elite

Elite G-8 Reach-In Test Chamber

The Elite G-8 Series reach-in environmental test chamber offers 8 cu. ft. or 226 liters (24″ x 24″ x 24″) of internal workspace. Single-stage or cascade refrigeration offers users a wide performance range to achieve complex test requirements, while optional boost cooling provides cryogenic fluid injection to expedite pulldowns and decrease cooling times.

Equipped with temperature only or temperature and humidity systems, the G-8 Elite Series humidity conditioning chamber offers industry-leading performance, flexibility, and reliability.

- Temperature Range:

- -70˚C to +180˚C (-94˚F to +356˚F) in cascade configurations

- -32˚C to +180˚C (-26˚F to +356˚F) in single-stage configuration*

- Humidity Range:

- 10% to 95% RH within the bounds of a +85˚C (+185˚F) max dry bulb and a +4˚C (+40˚F) min dewpoint

- Three-sided access to base mounted system components

- Continuous TIG welded 304 stainless interior liner

- Non-settling oven grade fiberglass insulation

- Chamber floor drain

- Dual silicone one-piece door gaskets with mitered and vulcanized corners

- Multi-pane tempered heated viewing window minimizes condensation

- Durable, maintenance free powder coat finish *custom colors available

- 3” access port on right-hand side wall (additional sizes available)

- Heavy duty swivel casters with integrated leveling pads

- Shelf pilaster for optional stainless steel shelves

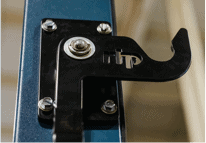

- Proprietary single-hand door latch

- Refrigeration service manifolds with gauges

- Quick response vapor generator with replaceable Inconel immersion heaters

- Vapor generator failsafe overtemp protection

- Humidity water demineralizer with one

- russellsOne touchscreen temperature and humidity programmer/controller

- Auto restart timer to automatically restart chamber after power outage

- Side mounted control panel for unique configuration requirements

- Product Temperature (Cascade) Control

- Stainless steel adjustable shelf

- Sliding shelf brackets

- Additional access ports and shelves

- Portable Conditioning Unit (PCU) adder with ducts

- Cable slot in door mullion

- Padlock hasp (lockable open/closed position)

- Humidity water recirculation system

- LN2 or CO2 boost cooling

- Dry air purge to minimize migrating moisture and condensation to control humidity

- GN2 purge system to mitigate condensation and control humidity

- Air-cooled or water-cooled refrigeration condenser

- Refrigeration sound-deadening package

- Boost heating

- Main power disconnect switch

- Control panel mounted E-Stop

- Running time meter

- Minimal spark options for battery testing and potentially hazardous test articles

- High heat options (temperature only models)

- Multiple voltage options

- NRTL/eSAFE inspection

- Single stage or cascade refrigeration

- Zero ozone depletion refrigerants

- Cryogenic models available

- Heat only models available

- Copper tube/aluminum fin cooling coil

- High efficiency brazed plate cascade heat exchanger

- Non-bucking automatic heat/cool mode selection with compressor time-out

- Dual high/low refrigeration pressure limit switches

- Inherent compressor overload protection

- Watlow F4T programmer/controller

- Ethernet Modbus TCP communication

- Touchscreen control interface

- Robust graphing and datalogging capability

- Digital Product Safeguard high/low temperature limit with audible alarm

- Solid state humidity sensor

- UL 508A compliant control panel

- All wiring meets National Electric Code (NEC) standards

- System branch circuits individually fused

- 115v control circuitry with integrated isolation transformer

- Full system function switches and indicator lights

- System fault status indicators

- All wiring color coded and labeled

- High temperature failsafe limit

- Overview

- Features

- Optional Add-Ons

- Refrigeration

- Humidity

- Controls

- Electrical

- Specifications Get Quote

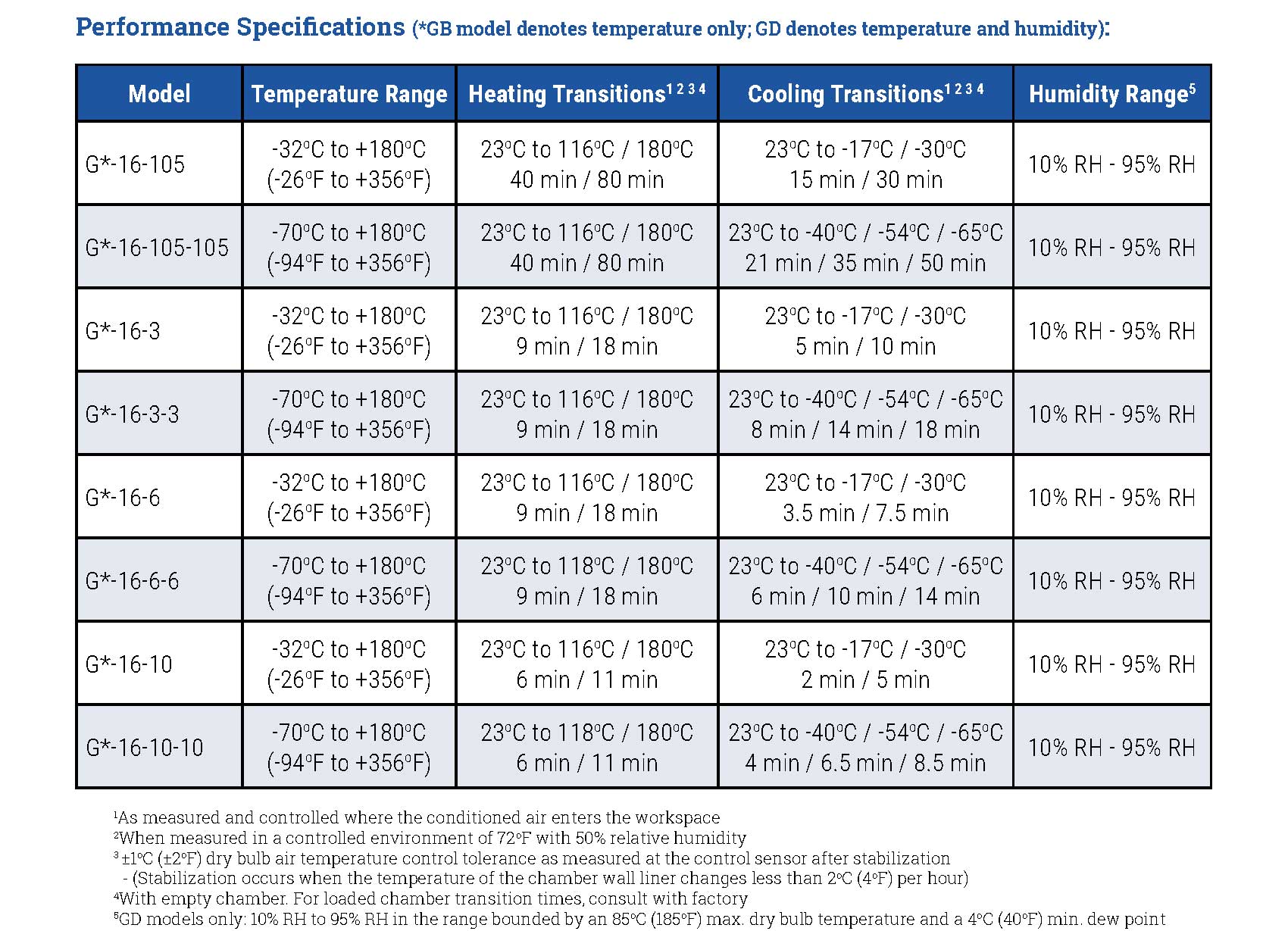

The G-16 Elite

Elite G-16 Reach-In Test Chamber

The Elite G-16 Series reach-in environmental test chamber offers 16 cu. ft. or 439 liters (30″ x 30″ x 30″) of internal workspace. Single stage or cascade refrigeration offers users a wide performance range to achieve complex test requirements, while optional boost cooling provides cryogenic fluid injection to expedite pull downs and decrease cooling times.

Equipped with temperature only or temperature and humidity systems, the G-16 Elite Series environmental test chamber offers industry leading performance, flexibility, and reliability.

- Temperature Range:

- -70˚C to +180˚C (-94˚F to +356˚F) in cascade configurations

- -32˚C to +180˚C (-26˚F to +356˚F) in single-stage configuration*

- Humidity Range:

- 10% to 95% RH within the bounds of a +85˚C (+185˚F) max dry bulb and a +4˚C (+40˚F) min dewpoint

- Three-sided access to base mounted system components

- Continuous TIG welded 304 stainless interior liner

- Non-settling oven grade fiberglass insulation

- Chamber floor drain

- Dual silicone one-piece door gaskets with mitered and vulcanized corners

- Multi-pane tempered heated viewing window minimizes condensation

- Durable, maintenance free powder coat finish *custom colors available

- 3” access port on right-hand side wall (additional sizes available)

- Heavy duty swivel casters with integrated leveling pads

- Shelf pilaster for optional stainless steel shelves

- Proprietary single-hand door latch

- Refrigeration service manifolds with gauges

- Quick response vapor generator with replaceable Inconel immersion heaters

- Vapor generator failsafe overtemp protection

- Humidity water demineralizer with one

- russellsOne touchscreen temperature and humidity programmer/controller

- Auto restart timer to automatically restart chamber after power outage

- Side mounted control panel for unique configuration requirements

- Product Temperature (Cascade) Control

- Stainless steel adjustable shelf

- Sliding shelf brackets

- Additional access ports and shelves

- Portable Conditioning Unit (PCU) adder with ducts

- Cable slot in door mullion

- Padlock hasp (lockable open/closed position)

- Humidity water recirculation system

- LN2 or CO2 boost cooling

- Dry air purge to minimize migrating moisture and condensation to control humidity

- GN2 purge system to mitigate condensation and control humidity

- Air-cooled or water-cooled refrigeration condenser

- Refrigeration sound-deadening package

- Boost heating

- Main power disconnect switch

- Control panel mounted E-Stop

- Running time meter

- Minimal spark options for battery testing and potentially hazardous test articles

- High heat options (temperature only models)

- Multiple voltage options

- NRTL/eSAFE inspection

- Single stage or cascade refrigeration

- Zero ozone depletion refrigerants

- Cryogenic models available

- Heat only models available

- Copper tube/aluminum fin cooling coil

- High efficiency brazed plate cascade heat exchanger

- Non-bucking automatic heat/cool mode selection with compressor time-out

- Dual high/low refrigeration pressure limit switches

- Inherent compressor overload protection

- Watlow F4T programmer/controller

- Ethernet Modbus TCP communication

- Touchscreen control interface

- Robust graphing and datalogging capability

- Digital Product Safeguard high/low temperature limit with audible alarm

- Solid state humidity sensor

- UL 508A compliant control panel

- All wiring meets National Electric Code (NEC) standards

- System branch circuits individually fused

- 115v control circuitry with integrated isolation transformer

- Full system function switches and indicator lights

- System fault status indicators

- All wiring color coded and labeled

- High temperature failsafe limit

- Overview

- Features

- Optional Add-Ons

- Refrigeration

- Humidity

- Controls

- Electrical

- Specifications Get Quote

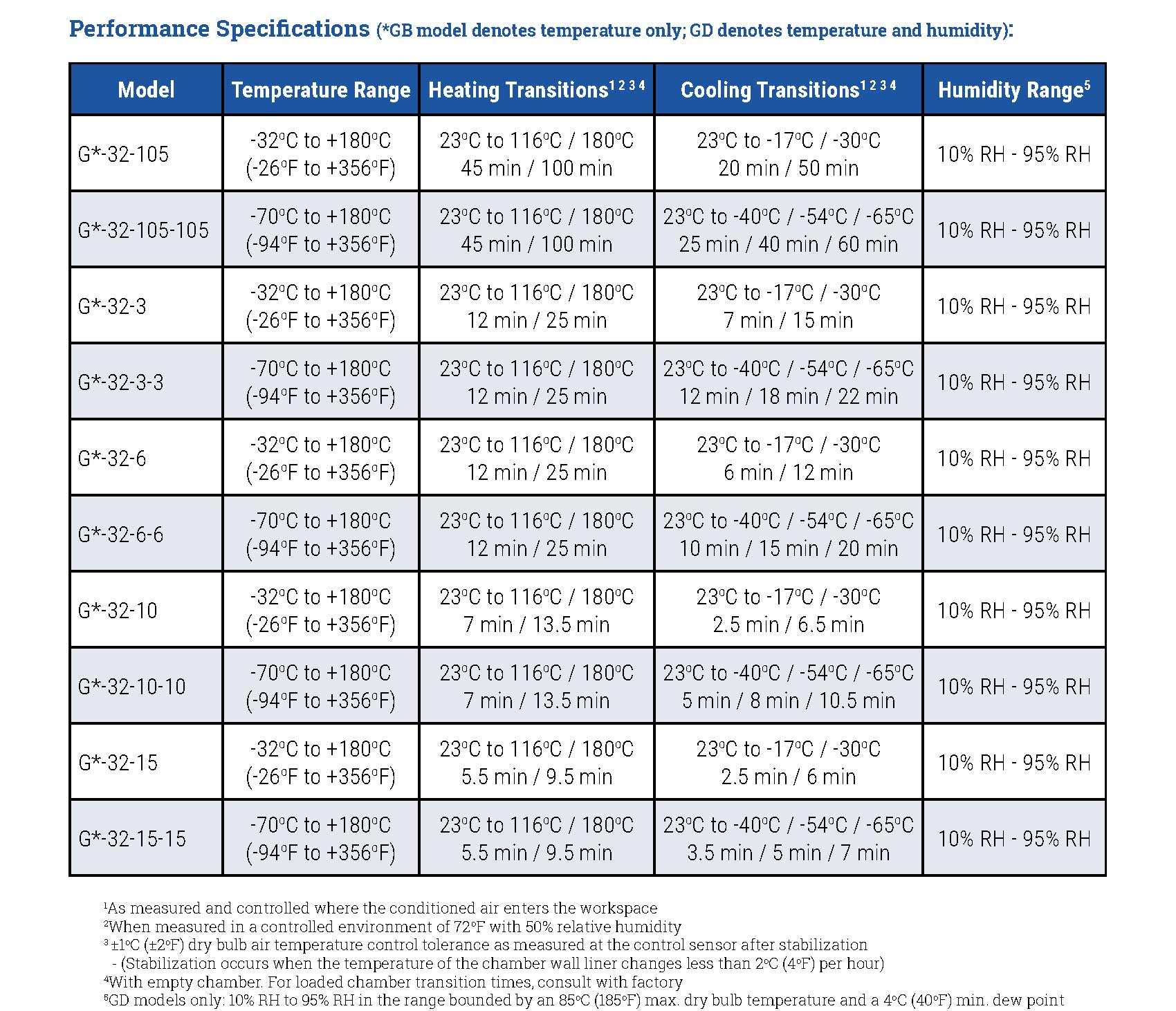

The G-32 Elite

Elite G-32 Reach-In Test Chamber

The Elite G-32 Series reach-in environmental test chamber offers 32 cu. ft. or 898 liters (38″ x 38″ x 38″) of internal workspace. Single stage or cascade refrigeration offers users a wide performance range to achieve complex test requirements, while optional boost cooling provides cryogenic fluid injection to expedite pull downs and decrease cooling times.

Equipped with temperature only or temperature and humidity systems, the G-32 Elite Series environmental test chamber offers industry leading performance, flexibility, and reliability.

- Temperature Range:

- -70˚C to +180˚C (-94˚F to +356˚F) in cascade configurations

- -32˚C to +180˚C (-26˚F to +356˚F) in single-stage configuration*

- Humidity Range:

- 10% to 95% RH within the bounds of a +85˚C (+185˚F) max dry bulb and a +4˚C (+40˚F) min dewpoint

- Three-sided access to base mounted system components

- Continuous TIG welded 304 stainless interior liner

- Non-settling oven grade fiberglass insulation

- Chamber floor drain

- Dual silicone one-piece door gaskets with mitered and vulcanized corners

- Multi-pane tempered heated viewing window minimizes condensation

- Durable, maintenance free powder coat finish *custom colors available

- 3” access port on right-hand side wall (additional sizes available)

- Heavy duty swivel casters with integrated leveling pads

- Shelf pilaster for optional stainless steel shelves

- Proprietary single-hand door latch

- Refrigeration service manifolds with gauges

- Quick response vapor generator with replaceable Inconel immersion heaters

- Vapor generator failsafe overtemp protection

- Humidity water demineralizer with one

- russellsOne touchscreen temperature and humidity programmer/controller

- Auto restart timer to automatically restart chamber after power outage

- Side mounted control panel for unique configuration requirements

- Product Temperature (Cascade) Control

- Stainless steel adjustable shelf

- Sliding shelf brackets

- Additional access ports and shelves

- Portable Conditioning Unit (PCU) adder with ducts

- Cable slot in door mullion

- Padlock hasp (lockable open/closed position)

- Humidity water recirculation system

- LN2 or CO2 boost cooling

- Dry air purge to minimize migrating moisture and condensation to control humidity

- GN2 purge system to mitigate condensation and control humidity

- Air-cooled or water-cooled refrigeration condenser

- Refrigeration sound-deadening package

- Boost heating

- Main power disconnect switch

- Control panel mounted E-Stop

- Running time meter

- Minimal spark options for battery testing and potentially hazardous test articles

- High heat options (temperature only models)

- Multiple voltage options

- NRTL/eSAFE inspection

- Single stage or cascade refrigeration

- Zero ozone depletion refrigerants

- Cryogenic models available

- Heat only models available

- Copper tube/aluminum fin cooling coil

- High efficiency brazed plate cascade heat exchanger

- Non-bucking automatic heat/cool mode selection with compressor time-out

- Dual high/low refrigeration pressure limit switches

- Inherent compressor overload protection

- Watlow F4T programmer/controller

- Ethernet Modbus TCP communication

- Touchscreen control interface

- Robust graphing and datalogging capability

- Digital Product Safeguard high/low temperature limit with audible alarm

- Solid state humidity sensor

- UL 508A compliant control panel

- All wiring meets National Electric Code (NEC) standards

- System branch circuits individually fused

- 115v control circuitry with integrated isolation transformer

- Full system function switches and indicator lights

- System fault status indicators

- All wiring color coded and labeled

- High temperature failsafe limit

- Overview

- Features

- Optional Add-Ons

- Refrigeration

- Humidity

- Controls

- Electrical

- Specifications Get Quote

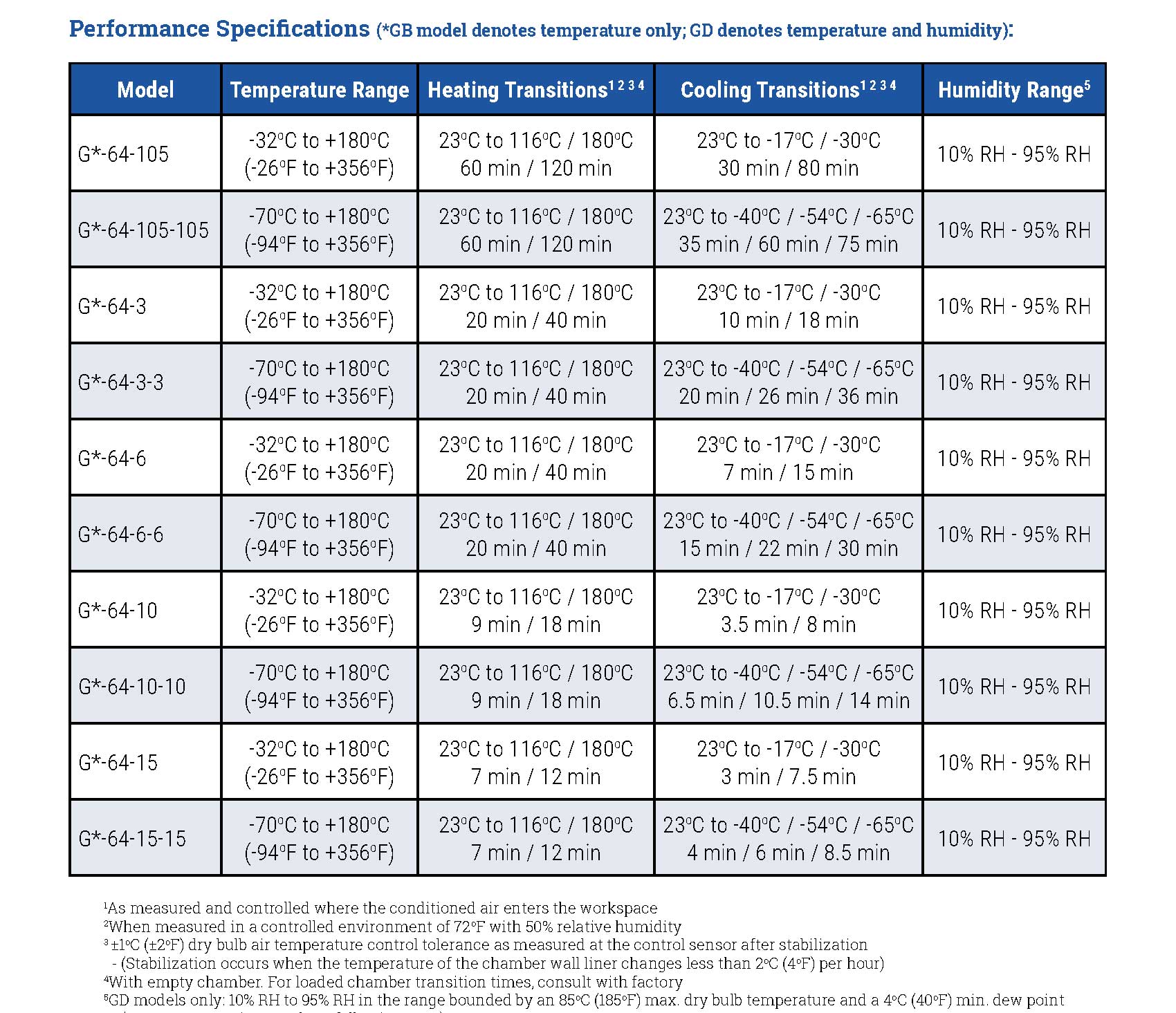

The G-64 Elite

Elite G-64 Reach-In Test Chamber

The Elite G-64 Series reach-in environmental test chamber offers 64 cu. ft. or 1,796 liters (48″ x 48″ x 48″) of internal workspace. Single-stage or cascade refrigeration offers users a wide performance range to achieve complex test requirements, while optional boost cooling provides cryogenic fluid injection to expedite pulldowns and decrease cooling times.

Equipped with temperature only or temperature and humidity systems, the G-64 Elite Series humidity conditioning chamber offers industry-leading performance, flexibility, and reliability.

- Temperature Range:

- -70˚C to +180˚C (-94˚F to +356˚F) in cascade configurations

- -32˚C to +180˚C (-26˚F to +356˚F) in single-stage configuration*

- Humidity Range:

- 10% to 95% RH within the bounds of a +85˚C (+185˚F) max dry bulb and a +4˚C (+40˚F) min dewpoint

- Three-sided access to base mounted system components

- Continuous TIG welded 304 stainless interior liner

- Non-settling oven grade fiberglass insulation

- Chamber floor drain

- Dual silicone one-piece door gaskets with mitered and vulcanized corners

- Multi-pane tempered heated viewing window minimizes condensation

- Durable, maintenance free powder coat finish *custom colors available

- 3” access port on right-hand side wall (additional sizes available)

- Heavy duty swivel casters with integrated leveling pads

- Shelf pilaster for optional stainless steel shelves

- Proprietary single-hand door latch

- Refrigeration service manifolds with gauges

- Quick response vapor generator with replaceable Inconel immersion heaters

- Vapor generator failsafe overtemp protection

- Humidity water demineralizer with one

- russellsOne touchscreen temperature and humidity programmer/controller

- Auto restart timer to automatically restart chamber after power outage

- Side mounted control panel for unique configuration requirements

- Product Temperature (Cascade) Control

- Stainless steel adjustable shelf

- Sliding shelf brackets

- Additional access ports and shelves

- Portable Conditioning Unit (PCU) adder with ducts

- Cable slot in door mullion

- Padlock hasp (lockable open/closed position)

- Humidity water recirculation system

- LN2 or CO2 boost cooling

- Dry air purge to minimize migrating moisture and condensation to control humidity

- GN2 purge system to mitigate condensation and control humidity

- Air-cooled or water-cooled refrigeration condenser

- Refrigeration sound-deadening package

- Boost heating

- Main power disconnect switch

- Control panel mounted E-Stop

- Running time meter

- Minimal spark options for battery testing and potentially hazardous test articles

- High heat options (temperature only models)

- Multiple voltage options

- NRTL/eSAFE inspection

- Single stage or cascade refrigeration

- Zero ozone depletion refrigerants

- Cryogenic models available

- Heat only models available

- Copper tube/aluminum fin cooling coil

- High efficiency brazed plate cascade heat exchanger

- Non-bucking automatic heat/cool mode selection with compressor time-out

- Dual high/low refrigeration pressure limit switches

- Inherent compressor overload protection

- Watlow F4T programmer/controller

- Ethernet Modbus TCP communication

- Touchscreen control interface

- Robust graphing and datalogging capability

- Digital Product Safeguard high/low temperature limit with audible alarm

- Solid state humidity sensor

- UL 508A compliant control panel

- All wiring meets National Electric Code (NEC) standards

- System branch circuits individually fused

- 115v control circuitry with integrated isolation transformer

- Full system function switches and indicator lights

- System fault status indicators

- All wiring color coded and labeled

- High temperature failsafe limit

- Overview

- Features

- Optional Add-Ons

- Refrigeration

- Humidity

- Controls

- Electrical

- Specifications Get Quote

The G-83 Elite

Elite G-83 Reach-In Test Chamber

The Elite G-83 Series reach-in environmental test chamber offers 83 cu. ft. or 2,350 liters (48″ x 48″ x 62″) of internal workspace. Single-stage or cascade refrigeration offers users a wide performance range to achieve complex test requirements, while optional boost cooling provides cryogenic fluid injection to expedite pulldowns and decrease cooling times.

Equipped with temperature only or temperature and humidity systems, the G-83 Elite Series humidity conditioning chamber offers industry-leading performance, flexibility, and reliability.

- Temperature Range:

- -70˚C to +180˚C (-94˚F to +356˚F) in cascade configurations

- -32˚C to +180˚C (-26˚F to +356˚F) in single-stage configuration*

- Humidity Range:

- 10% to 95% RH within the bounds of a +85˚C (+185˚F) max dry bulb and a +4˚C (+40˚F) min dewpoint

- Three-sided access to base mounted system components

- Continuous TIG welded 304 stainless interior liner

- Non-settling oven grade fiberglass insulation

- Chamber floor drain

- Dual silicone one-piece door gaskets with mitered and vulcanized corners

- Multi-pane tempered heated viewing window minimizes condensation

- Durable, maintenance free powder coat finish *custom colors available

- 3” access port on right-hand side wall (additional sizes available)

- Heavy duty swivel casters with integrated leveling pads

- Shelf pilaster for optional stainless steel shelves

- Proprietary single-hand door latch

- Refrigeration service manifolds with gauges

- Quick response vapor generator with replaceable Inconel immersion heaters

- Vapor generator failsafe overtemp protection

- Humidity water demineralizer with one

- russellsOne touchscreen temperature and humidity programmer/controller

- Auto restart timer to automatically restart chamber after power outage

- Side mounted control panel for unique configuration requirements

- Product Temperature (Cascade) Control

- Stainless steel adjustable shelf

- Sliding shelf brackets

- Additional access ports and shelves

- Portable Conditioning Unit (PCU) adder with ducts

- Cable slot in door mullion

- Padlock hasp (lockable open/closed position)

- Humidity water recirculation system

- LN2 or CO2 boost cooling

- Dry air purge to minimize migrating moisture and condensation to control humidity

- GN2 purge system to mitigate condensation and control humidity

- Air-cooled or water-cooled refrigeration condenser

- Refrigeration sound-deadening package

- Boost heating

- Main power disconnect switch

- Control panel mounted E-Stop

- Running time meter

- Minimal spark options for battery testing and potentially hazardous test articles

- High heat options (temperature only models)

- Multiple voltage options

- NRTL/eSAFE inspection

- Single stage or cascade refrigeration

- Zero ozone depletion refrigerants

- Cryogenic models available

- Heat only models available

- Copper tube/aluminum fin cooling coil

- High efficiency brazed plate cascade heat exchanger

- Non-bucking automatic heat/cool mode selection with compressor time-out

- Dual high/low refrigeration pressure limit switches

- Inherent compressor overload protection

- Watlow F4T programmer/controller

- Ethernet Modbus TCP communication

- Touchscreen control interface

- Robust graphing and datalogging capability

- Digital Product Safeguard high/low temperature limit with audible alarm

- Solid state humidity sensor

- UL 508A compliant control panel

- All wiring meets National Electric Code (NEC) standards

- System branch circuits individually fused

- 115v control circuitry with integrated isolation transformer

- Full system function switches and indicator lights

- System fault status indicators

- All wiring color coded and labeled

- High temperature failsafe limit

CUSTOM REACH-IN TEST CHAMBERS

Our custom reach-in test chambers are designed for rigorous environmental testing capacity. Each custom reach-in test chamber is tailored to your exact sizing specifications and requirements, offering thermal testing, temperature cycling, temperature/humidity, and steady-state temperature and or humidity testing capabilities.

Unique customer test specifications and requirements require unique testing solutions. Our custom-engineered reach-in environmental test chambers offer the widest range of testing capabilities, each specifically designed to our customer’s exact specifications. Virtually limitless options for internal and external dimensions, temperature, humidity, or combined environment are offered.

- Customer provided interior sizes

- Brushed 304 series stainless steel liner, heliarc welded and dye checked

- Fiberglass insulation, .25k factor

- Welded steel frame

- Custom engineered chamber door with dual gaskets

- Removable access panels to serviceable components

- Durable blue enamel finishes (custom colors available)

- Multipane tempered heated window

- Microprocessor temperature/humidity programmer

- Temperature range for single stage refrigeration:

- -22˚F/-30˚C to 356˚F/180˚C

- Temperature range for cascade refrigeration:

- -100˚F/-73˚C to 356˚F/180˚C

- Change rates from 9˚F/5˚C/min. to 36˚F/20˚C/min. (Faster rates achieved with LN2 cooling)

- Humidity range:

- 10% to 95% RH within the bounds of a 185°F/85°C max. dry bulb and a 40°F/4°C min. dewpoint

- Can be equipped with battery testing safety features according to EUCAR hazard safety level

- Damper systems

- Refrigeration gauges

- Refrigeration sound deadening package

- LN2/CO2 cooling

- Air cooled condenser (integral or remote)

- Humidity water demineralizer

- Dry air purge system

- Desiccant dehumidifier

- Running time meter

- Electrical disconnect switch

- RussellsOne controller

- Solid state humidity sensor on humidity models

- Product safeguard redundant over/under temperature limit

- Circular or electronic chart recorders

- Free standing remote instrument console

- Computer communications, networking, data-logging software

- Low or zero ozone depletion refrigerants

- Energy saving refrigeration bypass capacity control

- Low stage desuperheater

- Oil pressure switches

- Compressor suction and discharge pressure switches

- Water cooled condenser

- Vapor tank and condenser ASME certified

- Compressor overload protection

- High-stage compressor crankcase heater

- Compressor head fans

- Low-stage oil separator

- All piping joints silfos or silver soldered

- Stainless steel compressor condensate pans

- Quick response vapor generator with replaceable Inconel® sheath immersion heater

- Vapor generator failsafe overtemp protection

- Humidity water demineralizer

- Humidity range: 10% RH to 95% RH

- Watlow microprocessor programming controller

- Self prompting operation with 256 programmable segments

- Digital failsafe product safeguard test item temperature limit

- Ethernet Modbus TCP communication

- Touchscreen control interface

- Robust graphing and datalogging capability

- All wiring meets NEC standards

- 120v control circuit transformer

- Fully enclosed electrical panel

- All circuits fused or circuit breaker protected

- Full system function switches with system status pilot lights

- Incandescent interior lighting

- All wiring numbered or color coded

- High Temperature limit safety

- Master heating circuit contactor

- Air circulator/heater interlock

- Balanced load on three phase power