Thermal testing is a critical validation process that evaluates how products, materials, and components perform under varying temperature conditions. From consumer electronics to aerospace systems, thermal testing ensures reliability, safety, and performance across the operational temperature range. For manufacturers in competitive industries, comprehensive thermal testing isn’t just quality assurance—it’s a regulatory requirement and a key to market success.

Understanding Thermal Testing Fundamentals

At its core, thermal testing subjects products to controlled temperature environments to identify potential failures, validate design specifications, and ensure consistent performance across expected operating conditions. Unlike ambient testing, thermal testing pushes products beyond normal operating parameters to reveal weaknesses before they reach customers.

Engineers use thermal testing to answer critical questions: Will this battery pack perform safely at -40°C? Can this electronic assembly withstand desert heat at 85°C? How does thermal cycling affect solder joint integrity over 10,000 cycles? These questions require sophisticated testing methodologies and precision equipment to answer accurately.

Primary Thermal Testing Methods

Temperature Cycling exposes products to repeated temperature transitions between hot and cold extremes. This method reveals failures caused by thermal expansion and contraction, particularly in assemblies with different material coefficients. Temperature cycling is essential for electronics validation, where solder joints, component leads, and PCB materials experience stress with each thermal transition.

Thermal Shock Testing takes temperature cycling to the extreme, subjecting products to rapid temperature changes—often transitioning 100°C or more in seconds. This accelerated approach quickly identifies design weaknesses and material incompatibilities that might take years to manifest in normal use. Thermal shock testing is particularly valuable for automotive and aerospace applications where products must withstand extreme environmental conditions.

Steady-State Temperature Testing maintains products at constant high or low temperatures for extended periods, validating performance at operational extremes. This method is crucial for products designed for extreme climates, from arctic research equipment to industrial systems in hot manufacturing environments.

Temperature and Humidity Testing combines thermal stress with moisture to simulate real-world environmental conditions. Many electronic and mechanical failures result from the interaction between temperature and humidity rather than either factor alone. This combined approach provides more realistic validation than temperature testing in isolation.

Industry Applications Across Sectors

The automotive industry relies heavily on thermal testing to validate everything from battery systems to infotainment displays. Electric vehicle batteries undergo extensive thermal testing to ensure safety across temperature extremes, while traditional automotive components must function reliably from Alaska to Arizona.

In aerospace and defense, thermal testing validates mission-critical systems that must operate in conditions from high-altitude cold to direct sunlight exposure. Satellite components, avionics, and weapons systems all require thermal qualification before deployment.

Consumer electronics manufacturers use thermal testing to prevent field failures and ensure product longevity. Smartphones, laptops, and IoT devices all undergo thermal validation to guarantee performance across global markets with vastly different climates.

The pharmaceutical industry depends on thermal testing for stability studies, ensuring drugs and vaccines maintain efficacy throughout their shelf life under various storage conditions.

Choosing the Right Thermal Testing Approach

Effective thermal testing requires careful consideration of several factors: the product’s intended operating environment, relevant industry standards (MIL-STD, IEC, ISO), and the specific failure modes being investigated. Temperature rate of change, dwell times, and the number of cycles all impact test effectiveness and must align with validation objectives.

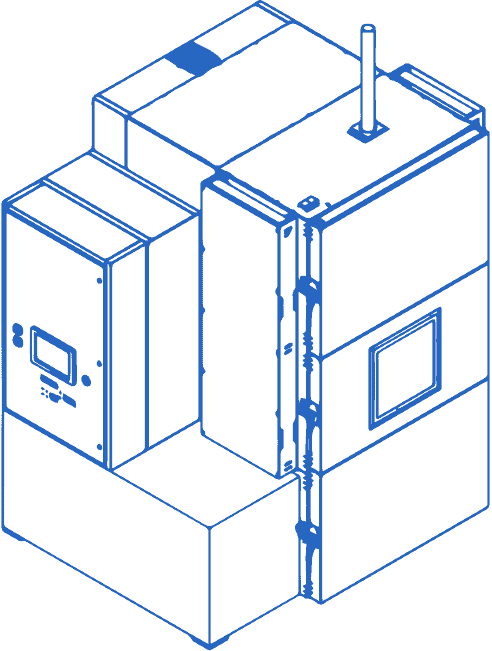

Modern thermal test chambers offer programmable profiles, precise temperature control, and data logging capabilities that enable sophisticated testing protocols. When selecting thermal testing equipment, consider chamber size, temperature range, ramp rates, and uniformity specifications to ensure capabilities match your validation requirements. The right thermal testing infrastructure provides the foundation for reliable product development and regulatory compliance across industries.