The COVID-19 pandemic has shifted the way we think about work, specifically related to our relationship with remote work. As we navigate the future of employment from remote locations, the evidence suggests the adjustments may in fact remain indefinitely. Pre-pandemic, estimates figured roughly five percent of employees worked remotely, while that amount is subject to settle at or around 20-30 percent depending on geography and industry.

Research suggests the shift to remote work has positively impacted productivity. One recent study revealed some ninety-four percent of employers reporting productivity at or above pre-pandemic levels, indicating that the perception of remote work has changed to support a potentially large, permanent increase in remote work.

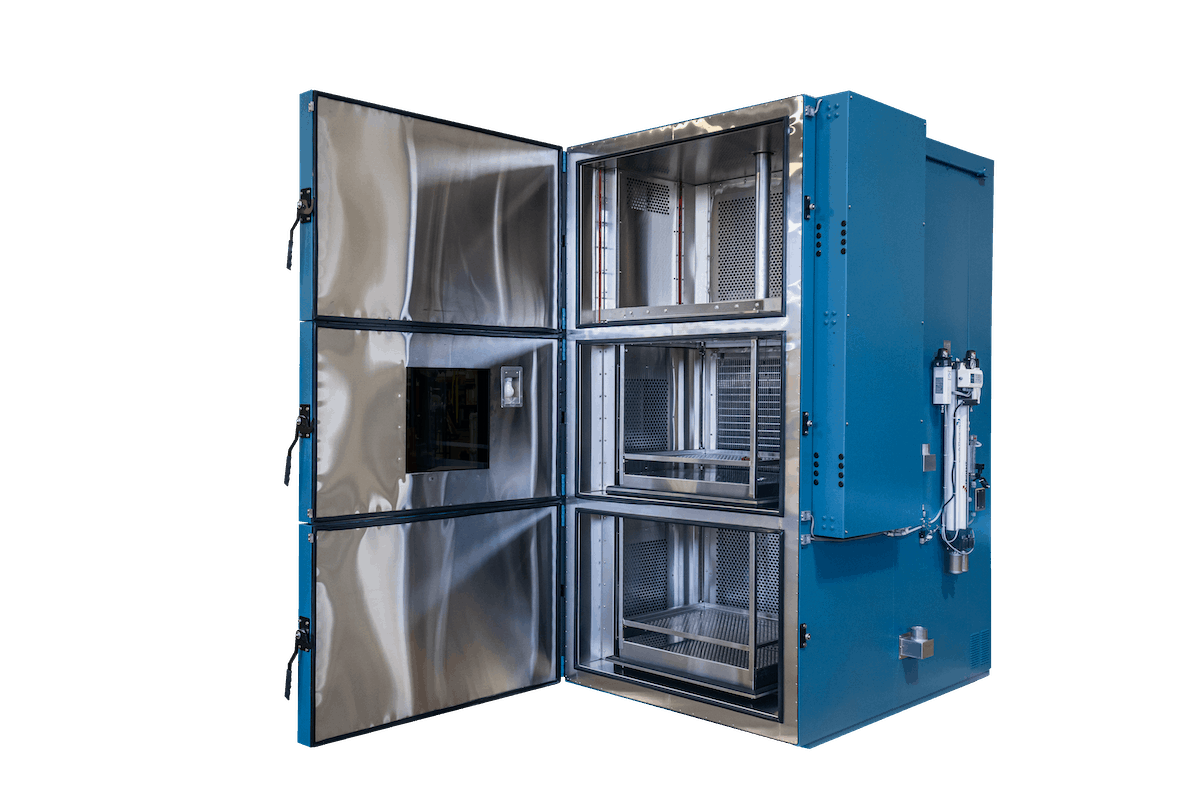

This shift presents new challenges for organizations involved in routine and complex testing using environmentally controlled test chambers. Attention to detail is critical, and a hands-on approach has historically been required to ensure tests are completed accurately and effectively.

A Simple Interface with Powerful Flexibility

The ability to manipulate and operate your test chambers remotely is critical to moving your testing forward without interruption or downtime.

Organizations today that routinely utilize environmental test chambers demand the ability to monitor and conduct complex testing from anywhere, with the ability to share results and collaborate efficiently.

Fortunately, the Russells One Chamber Controller provides a simple user interface with powerful data collection and unprecedented flexibility, allowing users to conduct tests from anywhere on a laptop, desktop, or tablet. Whether you run benchtop battery testing, temperature and humidity chamber profiles, or complex altitude or rapid decompression, the russellsOne can handle it all – remotely.

With reliable operator control over ethernet, a technician needs only to place the unit under test (UUT) into the workspace, while remote associates can run standard or complex profiles by logging into the built-in network server. Additionally, this allows custom programs, such as those written with LabView, C#, or C++ (among others) to integrate remote customer systems with the chamber’s operation.

Embracing the Current Remote Climate

Whether you operate a lab or a shared-lab space, you can feel confident in your ability to navigate your testing requirements and responsibilities remotely. Because the russellsOne offers data logging once per second every moment the chamber is turned on, you can quickly load and display data from dozens of sensors over time domains ranging from seconds to months. And since all your data is housed on your network server, it makes it easy to share responsibilities and collaborate remotely.

While the russellsOne is offered on any of our models, from humidity chambers to dynamometer chambers, we’ll also retrofit your equipment from any test chamber manufacturer with a russellsOne chamber controller to fit any chamber or console configuration. We put the user in control, offering various access levels and activity logging, so you can diagnose and prevent potential problems before they become costly. And since we provide the ability to retrofit various test chambers from different manufacturers, you can have the most powerful and robust data collection controls while not having to frequently replace a complete chamber.

With the russellsOne, organizations and end-users can adopt the remote work revolution with confidence.