Thermal cycling testing is designed to enhance the strength, reliability, and quality of products and components. These tests generally require a quick, uniform, and reproducible change in temperature over a set number of cycles according to industry test standards.

When you need an environmental test chamber with a high rate of temperature change, uniformity, and reproducibility, we recommend referencing your test standards against the dimensions, temperature cycling rate, and overall temperature range of the chamber to determine the best fit.

Below are a few common questions we receive regarding our temperature chambers or thermal cycling chambers.

1. What temperature change rates are available in a thermal cycling chamber?

Many factors influence the temperature change rate in a thermal cycling chamber. The size of the chamber, the number, weight, and material composition of the samples under test, and the starting and ending temperatures are just a few to consider.

Generally, temperature change rates of up to 15°C per minute can be produced in a mechanically cooled chamber depending on compressor size and configuration. Adding direct-injected liquid nitrogen supplemental or boost cooling can dramatically reduce cool-down and diminish temperature transition times.

2. What size thermal cycling chambers are available?

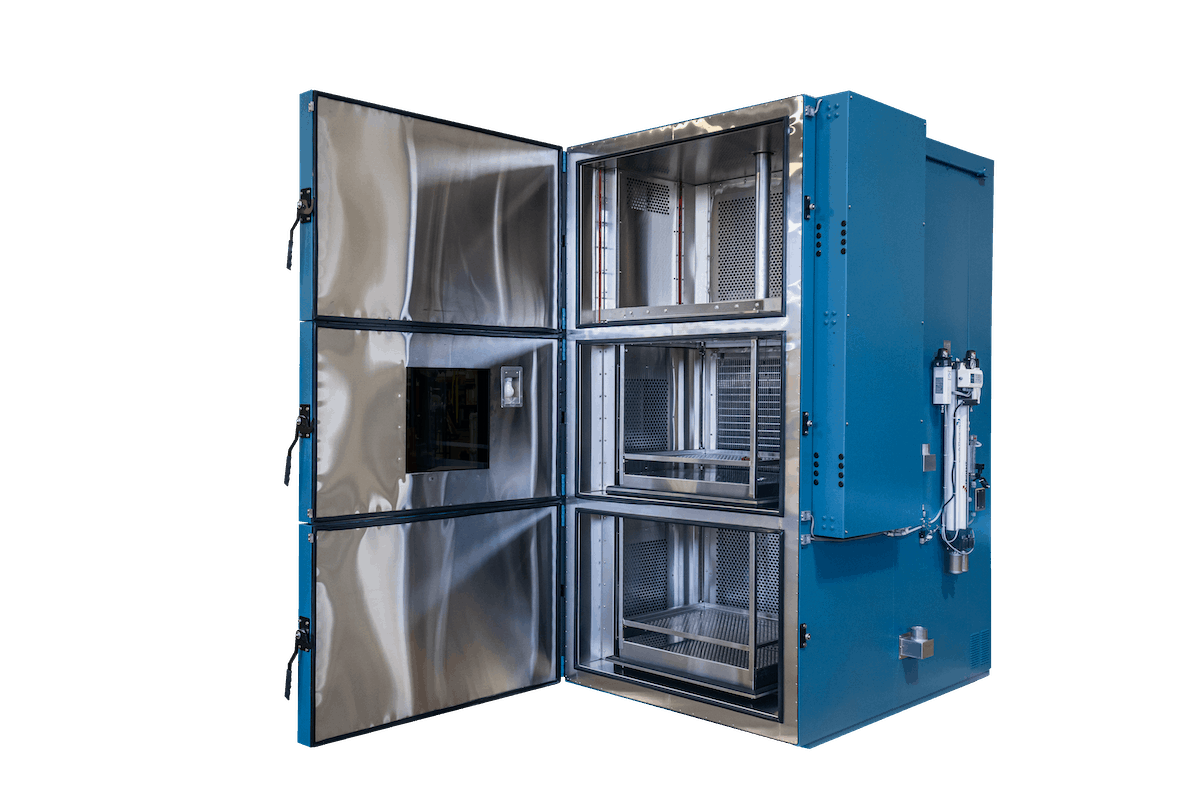

Like most environmental test chambers, thermal cycling chambers are available in a wide range of sizes. For example, our smallest test chamber has an 8 cu. ft. interior capacity, is equipped with reach-in shelves, and fits through a standard doorway on rolling casters.

Larger units are available depending on the size and quantity of the test sample. Walk-in or drive-in test chambers, for example, are fully customizable to your exact specifications and requirements. An important consideration to remember, in general, the larger the interior volume of the thermal cycling chamber, the greater capacity of cooling and heating power is required to achieve and maintain rapid temperature transition.

3. Do you offer humidity with your thermal cycling chambers?

Some test standards do require a temperature and humidity-controlled environment. Based on your requirements and testing profile, humidity is available within a standard range of 10% to 95% RH.

It is important to understand temperature and humidity control considerations as they relate to thermal cycling chambers. In general, the warmer the air, the more moisture it can hold within the same volume of space. Therefore it takes significantly more water vapor to elevate the relative humidity of air as it increases in temperature.

The opposite is true as the air cools. Due to this fact, 50% RH at a dry bulb temperature of 85°C is an exponentially higher moisture level than 50% RH at a dry bulb temperature of 10°C.

4. What available options do you recommend?

Many optional features are available depending on your testing requirements. We typically recommend a few key options based on improving uniformity and reproducibility within a given test.

A compressed dry air purge is helpful to reduce the dew point of the chamber supply air. This protects moisture-sensitive test samples and also reduces condensation during rapid temperature transitions.

Liquid nitrogen boost cooling is a direct injection system used to enhance the temperature cooling rate and produce faster temperature pulldowns.

A product temperature control thermocouple provides precise temperature measurement and control, directly at the sample. This is especially useful for providing quick temperature recovery during transitions by overshooting the temperature setpoint until the product temperature reaches the desired temperature level.

5. What types of controllers are available?

Our most popular and frequently used controller is the Watlow F4T, a proportional-integral-derivative (PID) color touchscreen controller capable of storing up to 40 different profiles. It conveniently offers an ethernet interface for remote monitoring and operation as well as USB ports for download and storage.

For more robust capabilities, we offer our own russellsOne® color touchscreen controller in a 12” human-machine interface (HMI) format. Data logging is available with up to 64 analog inputs and 4 channels of PID control. With its ability to interface with other software, it is our most frequently retrofitted controller to existing and other test chamber manufacturers’ equipment.

6. Do I have access to service and technical support after delivery?

We offer an industry-leading parts and service warranty on all our equipment, including our thermal cycling chambers. Purchasing an environmental test chamber is a significant investment. That’s why we’re proud to provide timely, friendly, and economical service to our customers.

Our dedicated service team is available to meet your needs if and when issues arise. And because we offer a preferred service provider network across our delivery footprint, you’re not handcuffed to one vendor or having to wait for service when your test equipment is down. Whether you call our factory or reach out online, you will receive prompt and effective solutions from our dedicated staff.

If you have questions or are interested in a thermal cycling chamber, contact us today to begin a conversation.